Cascade Catalysis

Cascade catalysts can be designed to perform multistep catalytic reactions in one-pot in water, which helps to greatly reduce the waste of solvents and energy. Cascade catalysis is therefore an important element in creating a more sustainably industry. To create cascade catalysts, the local separation of the reactive centres is key. Compartmentalization is a fundamental concept in nature that allows organisms to separately store, convert, and transport matter. Self-assembled compartments allow the site-isolation of catalysts to suppress cross-reactions and to induce concentration gradients for directed transport. We seek to imitate these compartments with polymers to strictly separate “wolf and lamb” catalysts from each other. Water-dispersible multicompartment reactors are either prepared through seeded growth emulsion polymerization or through self-assembly of specially designed block copolymers.

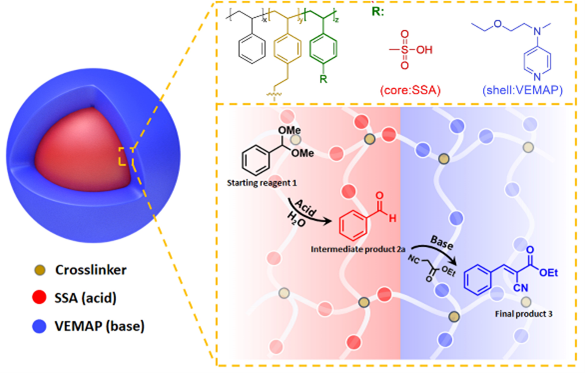

Core-Shell Microparticles

One system comprises the synthesis of core–shell microparticles (CSMs) by surfactant-free emulsion polymerization (SFEP). Thereby, an acid catalyst was placed in the core and a base catalyst in the shell. The organocatalytic monomers were separately copolymerized in three synthetic steps allowing the spatial separation of incompatible acid and base catalysts within the CSMs. Importantly, a protected and thermo-decomposable sulfonate monomer was used as acid source to circumvent the neutralization of the base catalyst during shell synthesis, which was key to obtain stable, catalytically active cascade catalysts. These showed very good performance in an established one-pot model cascade reaction in various solvents (including water), which involved an acid-catalyzed deacetalization followed by a base-catalyzed Knoevenagel condensation. The CSMs are easily recycled, modified, and their synthesis is scalable, making them promising candidates for organocatalytic applications.

Chen C, Janoszka N, Wong CK, Gramse C, Weberskirch R, Gröschel AH, Angew. Chemie Int. Ed. 2020, 60, 237-241. doi: 10.1002/anie.202008104.

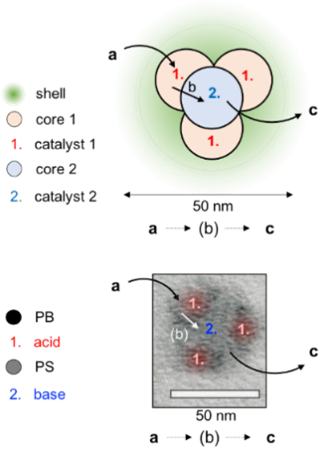

Multicompartment Nanoreactors

As an advancement to core-shell microparticles, we synthesize water-dispersible multicompartment nanoreactor (MCNRs) with self-assembly concepts. In addition to the benefits of performing multistep reactions in one-pot in water, the nanometer distance of the catalysts could speed up transport to and from the catalytic site thereby reducing reaction time and reduce side products. This project comprises the modification of individual compartments of MCMs currently designed from ABC triblock terpolymers. We already established the effect of block composition on nanoreactor shape and morphology and now equip blocks with organo-, organometallic and metal nanoparticle catalysts.

Text to figure: Design principle of a MCNR exemplified on a "clover" MCM.